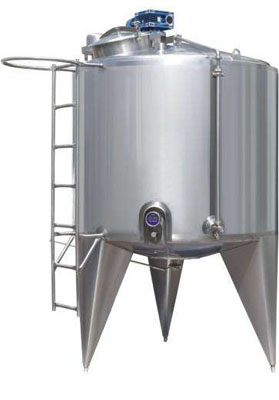

Prepare pot

Time:2019-12-27 14:43

Hot and cold tank (also named aging tank), cold hot cylinder energy saving, sound attenuation, corrosion, and the advantages of strong production capacity, easy clean, widely in the dairy industry, food, pharmaceutical, chemical, beverage and other industrial sectors, for heating, cooling, heat preservation, sterilization or slurry must be of stainless steel storage tank, especially suitable for the pasteurized milk and heat preservation, is a necessary equipment in ice cream production line.

Structure and function

Cold and hot cylinder structure drawing

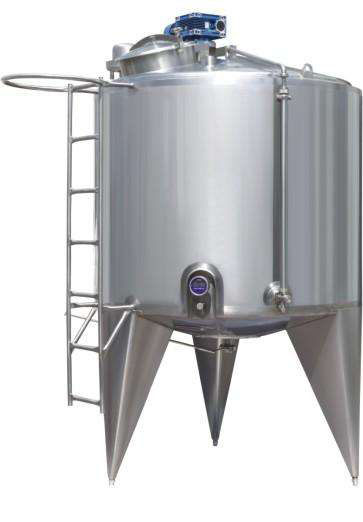

Cold and hot cylinder structure drawing

Structure: internal urchin, jacket, insulation layer, external foreskin, reducer, paddle, thermometer etc.

Bladder: made of stainless steel plate 304, surface polishing.

Middle layer jacket: use A3 steel plate or 1Cr18Ni9Ti steel plate, strengthen the spiral device, cold water from down to top (no pressure), achieve the best promotion and cooling purpose.

Insulation group: the stainless steel plate is cast into fish scales, and the insulation layer USES polyurethane or glass wool to maintain the temperature of the outside world, to achieve the thermal insulation effect.

Reducer: the cycloidal pin wheel planetary reducer, fixed on the bracket in the beam, the gear wheel shaft is connected with the paddle paddle, and it is connected by a live sleeve to facilitate unpacking and cleaning.

Thermometers: specification 00C~ 1000C, installation of the beam, straight out of the lowest medium position, so that the liquid can be used in the lowest position to indicate the temperature, to sterilization and aging purposes.

| Type | Production Capacity | Power | Speed | Weight |

| WJ-500 | 0.5m3 | 0.55kw | φ980*1800 | 220kg |

| WJ-800 | 0.8m3 | 0.55kw | φ1200*150 | 300kg |